Shanghai Fuyou Lord CHEMLOK 205 xabagta daweynta kulaylka

Dulmar

| Faahfaahin Deg Deg ah | |

| Meesha Asal ahaan | Shanghai, Shiinaha |

| Magaca Summada | chemlok |

| Nambarka Model | 205 |

| Adeegga Habaynta | Goynta |

| sumadda | Chem lok |

| Lambarka maqaalka | 205 |

| Habka daaweynta | heerkulka qolka |

| heerkulka shaqada | 65-82℃ |

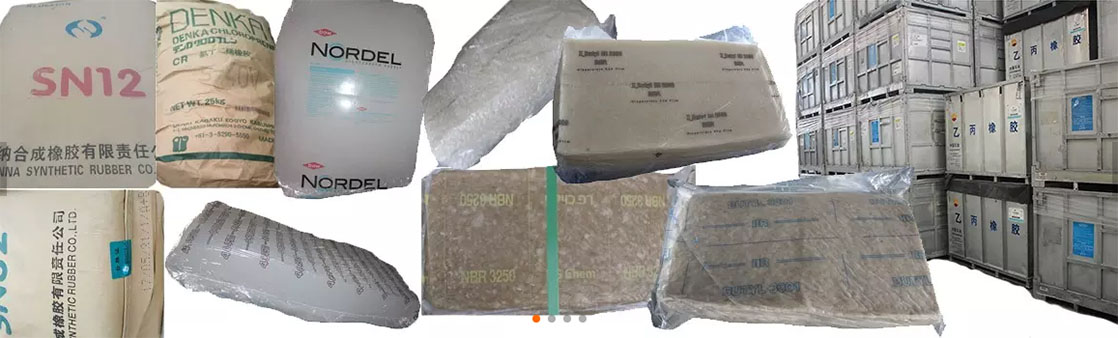

| taxane | Xabagta xabagta ee kuleylka lagu daaweeyo |

| Barta toosan | 18℃ |

| Midabka | Cawlan madmadow |

| Viscosity | 85-165cps |

| Cuf-jiid gaar ah | 0.91-0.97 |

| muddada ansaxnimada | 24 bilood |

| Awood-siinta | |

| Awood-siinta | 1000000 Tan/Tan bishii |

| Baakadaha & Bixinta | |

| Faahfaahinta Baakadaha | 1kg/fuusto! |

| Dekedda | dekedda shanghai iyo dekedda lianyungang |

Waqtiga Hogaaminta

| Tirada (Tons) | 1 - 1 | 2 - 10 | 11 - 100 | >100 |

| Est.Waqti (maalmo) | 10 | 15 | 30 | In laga wadahadlo |

Muuqaal

| Magaca Summada | Chem lok |

| Nambarka Model | 205 |

| Miisaanka | 1kg |

| viscosity | 85-165cps. |

Muuqaal

1. Aasaaska caalamiga ah.

2. Iyo birta, birta, aluminium, birta, copper, aluminium alloy iyo adhesion biraha kale.

3. Waxay leedahay iska caabin wanaagsan oo daxalka ah iyo iska caabbinta deegaanka.

Farsamada:

1. Daawaynta dusha sare: hoos u dhigista daawaynta farsamada ka dib (cammuudda qarxinta), ama daawaynta kiimikaad si meesha looga saaro saliidda warshadaynta, miridhka ama lakabka kale ee oksaydhka.Marka ciidda birta ah (kuul) loo isticmaalo in lagu buufiyo birta caadiga ah, birta la tuuro iyo biraha kale ee ferromagnetic, wakhtiga baarkinka ka dib daaweynta dusha sare waa in la xakameeyaa ka hor inta aysan soo noqnoqon oksaydhka iyo miridhku;buufinta ahama, aluminium, naxaas, zinc iyo biraha kale ee aan ferromagnetic ciid quartz waa in la dhammeeyaa 90 daqiiqo gudahood ka dib daaweynta dusha.

2. Isku darka: waa in si buuxda loo walaaqay ka hor inta aan la isticmaalin, waxaana la isticmaali karaa ka dib marka la gaaro isku darka labbiska.

3. Dilution: butanone ama methyl isobutyl waxa loo isticmaali karaa in lagu milo ch205.Marka la buufiyo, viscosity-ga waxaa lagu hagaajin karaa 18-20 4.second (Zahn 2 koob).Walaaqaya waa in si tartiib ah loogu daraa marka la walaaqayo.Si looga hortago roobabka ka dhasha shaqo-xumada.

4. Hababka dahaarka xabagta: habka wax lagu shubo, habka buufinta, habka daahan buraashka, habka dahaarka rullaluistemadka iyo habka wareejinta.

5. Dhumucda dahaarka xabagta: dhumucda filimka qalalan ee ch205 waxaa badanaa lagu dhejiyaa 5.1-10.2 μ M. Marka NBR keligiis la isticmaalo ama lagu daro xabagta taxanaha ch220, xadka sare ee dhumucda filimka ayaa la doortaa;codsiyada kale, qiimaha hoose ee xaddidan ee dhumucda filimka ayaa la doortaa.

6. Qalajinta: ku qallaji hawo nadiif ah ilaa 30-45 daqiiqo (heerkulka qolka) ka dib markaad dhejiso.65-82c foornada qarxinta waxay ku habboon tahay si degdeg ah oo dhammaystiran u engejinta qaybaha dahaarka leh.

7. Parking: haddii qaybaha dahaarka leh si fiican loo kaydiyo si looga fogaado saamaynta boodhka, saliidda iyo uumiga biyaha, waxa la kaydin karaa hal bil.

8. Daawaynta: marka qaybaha dahaarka leh lagu dhejiyo caaryada kulul, caaggu waa in si degdeg ah loo buuxiyaa, caaryadana waa in la xiro si looga hortago fashilka koollada sababtoo ah daaweynta hore, si loo hubiyo in koollada iyo caaggu ay yihiin kuwo jilicsan. isla mar ahaantaana, iyo sifooyinka isku xidhka ayaa la helay.

9. Waqtiga daawaynta: waxay ku xidhan tahay wakhtiga daawaynta iskudarka caagga ah.

Sharaxaada Alaabta

Shirkadda